A large number of solar installations today include batteries, and the number of energy storage systems is growing rapidly. As this trend continues, risks in homes increase due to more complex electrical installations involving solar panels, battery systems, and control systems.

This increase in risk is a natural part of development, as there are inherent dangers when high-power and high-energy batteries are installed in residential areas. Although the number of fires related to energy storage systems remains low, the rapid growth in installations raises the potential for more incidents.

During the development of the qapasity Arctic Series, safety was a crucial factor and a key reason why we chose to design semi solid-state batteries. In future posts, we will provide detailed explanations of why this battery chemistry is safer than traditional systems.

Statistics

Between 2018 and 2022, there were over 3,500 electrical fires and fire incidents in residential properties. According to a report by the Swedish Electrical Safety Authority (Link), only 14 of these were caused by solar installations, representing just 0.4% of all electrical fires in homes.

One of these 14 cases was an incident without any property damage, and in 5 of the 14 cases, the fire was caused by an associated battery. During this period, fire services responded to 54,194 fire-related incidents in buildings. Fires caused by rechargeable products increased by 42% over the five years. Electrical fires in residential homes most often originate in power outlets, particularly in kitchens, with stove misuse being the leading cause of such fires. The full report can be downloaded via this link.

It is essential to emphasize that fires in stationary energy storage systems are rare, especially since the significantly safer LFP technology is predominantly used (many widely reported electric vehicle fires involve NMC technology). Despite the low incidence of fires, safety is always a top priority. At qapasity, we aim to enhance safety even further through our unique semi solid-state battery cells, achieving even higher fire safety standards.

Thermal Runaway

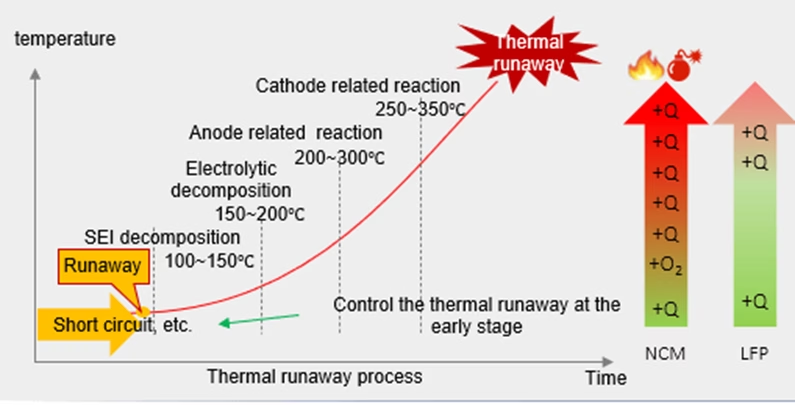

Thermal runaway occurs when a short circuit within a battery causes the temperature to rise. As the temperature increases, oxygen is released from the active materials in the battery’s chemical composition. This oxygen accelerates the reaction, generating more heat and releasing even more oxygen, a chain reaction that cannot be stopped. Even if the battery is submerged in water, foam, or other extinguishing agents, the fire can sustain itself using the oxygen generated by the battery material.

The difference between LFP and NMC batteries is striking when viewed from a fire safety perspective. NMC is a more unstable and flammable technology, while LFP is significantly safer. The key reason LFP batteries do not reach thermal runaway is that they do not generate enough heat, indicated by “Q” in the graph below, to release oxygen that would fuel a self-sustaining reaction.

Thermal runaway in NMC batteries vs. LFP batteries, which do not reach thermal runaway.

What makes an LFP battery safe?

LFP (lithium iron phosphate) batteries are considered one of the safest battery technologies for several reasons. Commonly cited safety factors include:

- Thermal stability: LFP batteries have higher thermal stability compared to other lithium-ion batteries. They are less prone to thermal runaway, reducing the risk of fire or explosion.

- Non-flammable electrolyte: While they use an organic electrolyte, the chemical composition in LFP batteries is less reactive and more stable under high temperatures and mechanical stress.

- Material choice: LFP cathodes are made of iron phosphate, a less reactive material with a lower risk of releasing oxygen when heated, which helps prevent fire.

- Lower energy density: LFP batteries have slightly lower energy density, meaning they store less energy per unit of weight. This can help reduce the risk of fire in case of a short circuit or improper handling.

How is LFP battery safety tested?

One common safety test for LFP batteries is the short-circuit test, often called the “nail test,” where a large nail punctures the battery to create a short circuit. During this test, the battery may begin to smoke and expand internally, but the temperature does not reach critical levels that would trigger thermal runaway (i.e., oxygen release).

Watch an example of the test here.

Conclusions

Lithium iron phosphate (LFP) is one of the safest battery technologies available. In addition to utilizing LFP, qapasity has further enhanced safety by removing flammable electrolytes in our semi solid-state batteries, making an already safe technology even safer.

In upcoming blog posts, we will continue to explore batteries and battery safety in greater depth. Subscribe to our newsletter to stay informed when the next post is published!